Top Trends in Brush Machine Factory Innovations

Top Trends in Brush Machine Factory Innovations

Blog Article

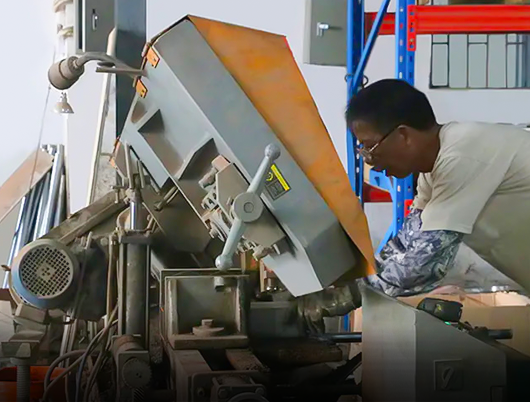

In the rapidly evolving landscape of manufacturing, brush machine factories are embracing innovative technologies to enhance their production capabilities and improve efficiency. As industries continue to demand higher precision and quality in products, companies like Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. are leading the charge with their advanced machinery. With 37 years of production experience, they have cultivated a wealth of knowledge that informs their approach to developing state-of-the-art brush making solutions.

The introduction of 2-5 axis machines has been a game changer for the industry, allowing for greater versatility and automation in production lines. These technological advancements not only streamline the manufacturing process but also ensure that factories can keep up with the dynamic needs of their clients. As we delve deeper into the top trends shaping the future of brush machine manufacturing, it is clear that innovation will play a pivotal role in driving success and meeting the high standards of today's market.

Overview of Brush Machine Innovations

Brush Manufacturing Process Explained

The brush manufacturing industry has seen significant advancements in technology, driven by the need for efficiency and precision. Innovations in brush machine design, particularly in the development of 2-5 axis machines, have enabled manufacturers to produce complex shapes and sizes with remarkable accuracy. These machines are designed to automate many processes that were previously manual, thereby reducing labor costs and increasing production speeds.

Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. stands at the forefront of this transformation. With 37 years of experience, the company has continuously refined its technologies, leading to enhancements in machine versatility and performance. Their focus on technical accumulation ensures that each new model brings improvements in productivity and quality, catering to the diverse needs of the brush market.

Furthermore, sustainability has become an essential element in brush machine innovations. Manufacturers are increasingly implementing eco-friendly practices in their production lines. This includes the use of recyclable materials and energy-efficient machines, which help reduce environmental impact while meeting the growing demand for sustainable products. As trends continue to evolve, the brush manufacturing sector appears poised for further innovation, aligning with global sustainability goals.

Technological Advancements in 2-5 Axis Machines

The evolution of 2-5 axis machines has transformed the brush manufacturing industry, making production processes more efficient and precise. With advanced computer numerical control (CNC) technology, these machines can perform complex operations with minimal manual intervention. This automation not only increases productivity but also ensures consistency in quality, which is crucial for companies that aim to maintain high standards in their products.

Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. has been at the forefront of these advancements, leveraging 37 years of experience and technical expertise. Their commitment to innovation has led to the development of machines that incorporate cutting-edge features such as intelligent software integration and enhanced user interfaces. These features enable operators to easily program and adjust machine settings, significantly reducing the learning curve and downtime associated with equipment setup.

Moreover, the materials and components used in the construction of 2-5 axis machines have also seen significant improvements. Durable materials and high-precision components contribute to the longevity and reliability of these machines. As manufacturers continuously seek ways to optimize their production lines, the integration of advanced sensors and monitoring systems has further pushed the boundaries, allowing real-time data processing and enabling predictive maintenance practices to prevent unexpected breakdowns.

Impact of 37 Years of Experience

The extensive experience of Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. plays a crucial role in its innovation and product development. With 37 years of dedicated service in the field, the company has accumulated a wealth of technical knowledge and expertise that helps it stay ahead of the competition. This experience allows them to refine their manufacturing processes continually, ensuring that they produce high-quality machines that meet the evolving needs of the brush industry.

Furthermore, the long-standing presence in the market has enabled Jiangmen Meixin to foster strong relationships with suppliers, customers, and industry partners. These connections are essential for staying informed about market trends and customer preferences. By leveraging this network, the company can quickly adapt its technology to align with the latest demands, enhancing its product offerings and ensuring long-term sustainability.

Lastly, the deep-rooted history of the company contributes to a strong culture of innovation. Experienced professionals within the organization are encouraged to share ideas and explore new technologies for improving machine design and functionality. This collaborative environment not only enhances creativity but also leads to breakthroughs that can transform the brush-making process, ultimately setting new standards within the industry.

Market Trends and Customer Demands

The brush machine industry is experiencing a shift driven by consumer preferences for higher quality and more sustainable products. As customers become more environmentally conscious, there is an increasing demand for machines that can efficiently produce eco-friendly brushes. Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. is at the forefront of this trend, utilizing advanced technology in their 2-5 axis machines to enhance production capabilities while reducing waste.

Additionally, customization has become a significant trend as businesses seek to differentiate themselves in a competitive market. Clients are looking for machines that not only produce standard brushes but can also handle specialized orders with varied designs and materials. This demand for versatility has led manufacturers to innovate and create adaptable machinery that meets the specific needs of their customers, thereby increasing product offerings and customer satisfaction.

Lastly, rapid technological advancements are reshaping the landscape of brush machine manufacturing. Automation and smart technology integration are on the rise, offering improved efficiency and precision. Customers expect machines that are user-friendly and equipped with the latest features, such as real-time monitoring and data analytics. Companies like Jiangmen Meixin are responding to these demands by continually investing in research and development to provide cutting-edge solutions that meet the evolving needs of the market.

Future Prospects for Brush Manufacturing

As the brush manufacturing industry continues to evolve, there is a strong emphasis on automation and advanced technologies. Companies like Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. are at the forefront of this transformation, incorporating 2-5 axis machines that enhance precision and efficiency. This shift not only speeds up production but also allows for customization to meet the diverse needs of consumers, paving the way for innovation in product design and functionality.

Sustainability is another key trend shaping the future of brush manufacturing. With increasing consumer demand for eco-friendly products, manufacturers are exploring the use of sustainable materials and green production processes. Jiangmen Meixin’s long-standing expertise positions it well to adapt to these changes, focusing on developing machines that support the use of biodegradable materials and minimize waste. This commitment to sustainability can significantly improve a company's competitive edge in the market.

Looking ahead, the integration of smart technologies such as IoT and data analytics is set to revolutionize brush factories. These innovations enable real-time monitoring and predictive maintenance of machinery, resulting in reduced downtime and operational costs. Companies leveraging these technologies can enhance their production capabilities and respond swiftly to market trends. The future of brush manufacturing is not only about efficiency but also about creating intelligent systems that support a more agile and responsive manufacturing environment.

Report this page